Events

Classes End – Spring Term

Last day of classes for the spring term.

Eye Ball & Opticianry Career Fair

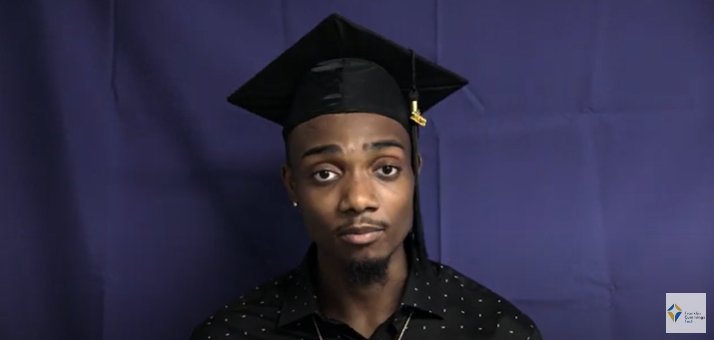

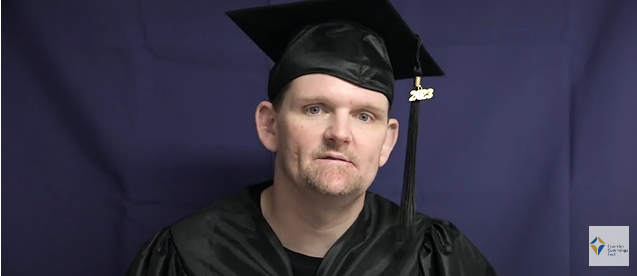

Celebrate Opticianry in Massachusetts at the 2024 Eye Ball, an evening of Introductions, Testimonials, Awards, and Appreciation with current Franklin Cummings Tech students, alumni,... Read more

Academic Awards Dinner

The Academic Awards Dinner is held to honor exceptional graduating students. Awardees are selected by faculty chairs from each academic department and the office... Read more